Theory of Operation

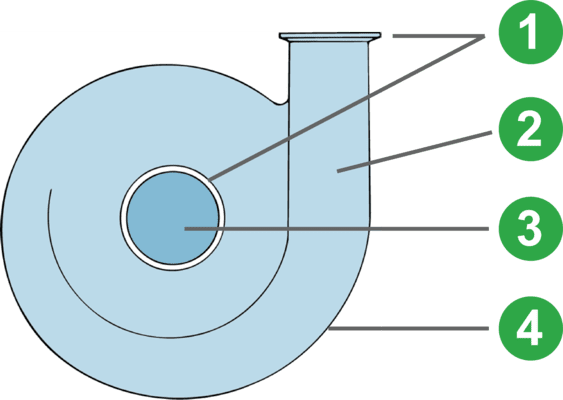

The Waukesha Volute Casing

(High Capacity Models are More Versatile)

The optimized Waukesha design performs more efficiently over a wide range of operating conditions. The efficient casing and port design maximize performance under low NPSH conditions.

1) Enlarged Ports

2) Investment Cast, or machined from solid (not stamped & welded)

3) Deeper, more efficient inlet “eye”

4) Volute casing (high capacity models), evens flow, minimizes turbulence

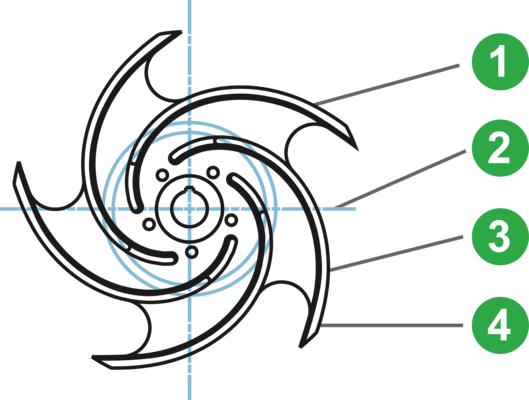

Waukesha’s Exclusive Impeller Design

The Waukesha impeller/shaft sleeve is a single, piece mounted rigidly on the motor shaft. Unlike C-flange mounted pumps, it stays aligned and performs with less vibration under the most rigorous operating conditions and maximizes seal life.

1) Exclusive one-piece impeller/shaft; eliminates impeller/hub wear

2) Top efficiency impeller

3) No clips or crevices to breed contaminants

4) Five blade impeller (4 blades on Model 2045)

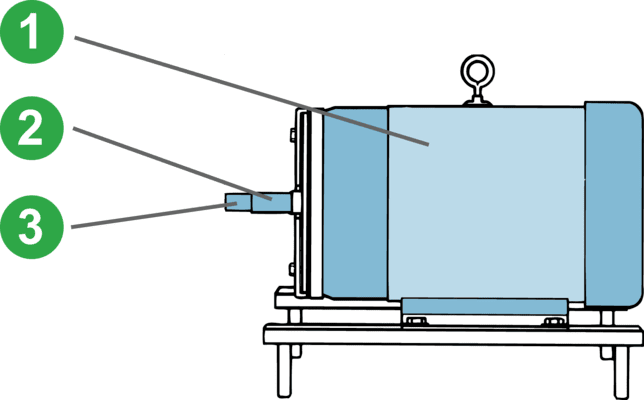

Offering Exclusive NEMA JM Frame Motors for both Sanitary and Industrial Applications

JM Frame Motors are specifically designed for centrifugal close coupled pumps and conform to NEMA, Hydraulic Institute and ANSI standards.

1) Heavier front bearing extends life

2) Extra large motor shaft increases rigidity, reduces vibration

3) Direct connecting impeller; no stub shaft required

Key Application

Food & Beverage |

Dairy |

Pharmaceutical & Cosmetic |

Chemical & Industrial |

|---|---|---|---|

|

|

|

|

Specifications

MODEL |

INLET |

OUTLET |

MAXIMUM

|

|

|

||

|---|---|---|---|---|---|---|---|

1750 RPM |

3500 RPM |

1750 RPM |

3500 RPM |

||||

2045 |

" (38mm)

|

1½"

|

4½"

|

97 GPM

|

190 GPM

|

22 ft.

|

88 ft.

|

2065LV |

1½" (38mm)

|

1½"

|

6½"

|

100 GPM

|

200 GPM

|

44 ft.

|

180 ft.

|

2065 |

2½"

|

2"

|

6½"

|

245 GPM

|

400 GPM

|

47 ft.

|

190 ft.

|

2065HV |

3"

|

2"

|

6½"

|

370 GPM

|

500 GPM

|

50 ft.

|

200 ft.

|

2075 |

3"

|

1½"

|

811/16"

|

125 GPM

|

300 GPM

|

80 ft.

|

320 ft.

|

2085LV |

2"

|

1½"

|

8½"

|

70 GPM

|

145 GPM

|

81 ft.

|

330 ft.

|

2085 |

3" (76mm)

|

2½"

|

811/16"

|

480 GPM

|

840 GPM

|

85 ft.

|

342 ft.

|

2105 |

4" (102mm)

|

4"

|

10½"

|

1400 GPM

|

N/A |

133 ft.

|

N/A |