Theory of Operation

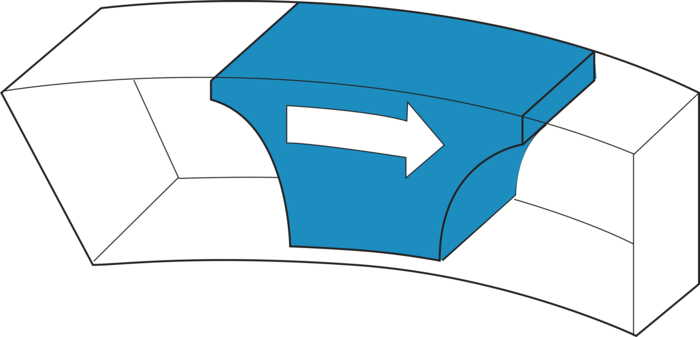

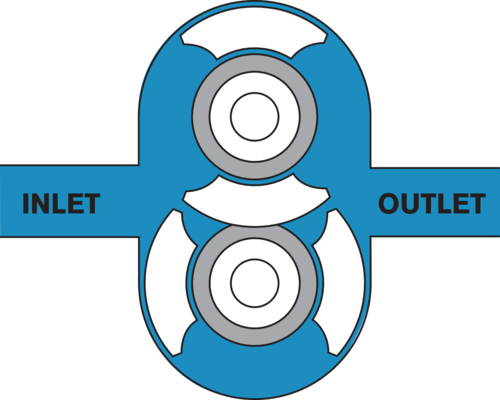

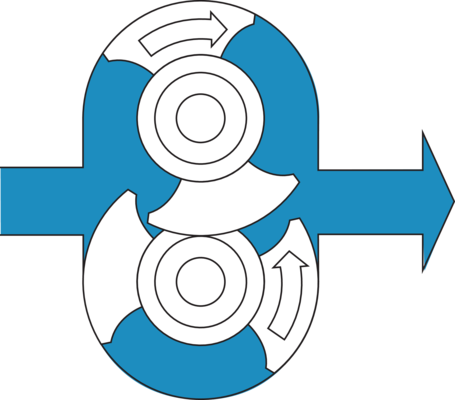

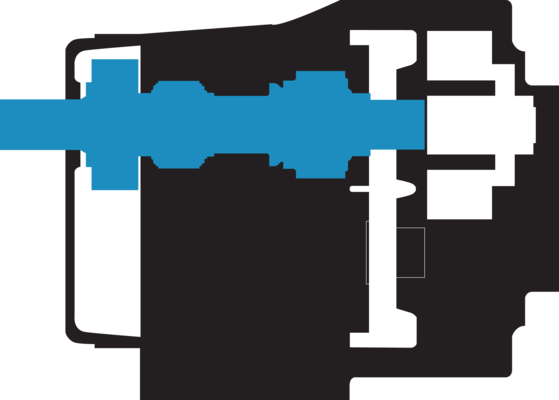

The Waukesha Universal Series of pumps use the time-tested circumferential-piston operating principle. The arc-shaped "pistons" (rotor wings) travel in annular-shaped cylinders machined in the pump body; the resulting long sealing path reduces slippage and produces a smooth flow of product without destructive pulses or pressure peaks and without valves or complex parts.

Because the rotors are made of Waukesha non-galling Alloy 88, the rotors can be run with exceptionally close clearance with the 316L stainless steel fluid head, without having to fear galling or seizing should inadvertent pressure surges cause contact. The close clearances combined with the rotor geometry, which gives a long sealing path between the pump inlet and outlet, means low slip operation even with low viscosity fluids. This means you get high efficiency, good priming ability, metering capability, and flow control everytime you use a Waukesha Universal Pump.

Additionally, because of the large fluid cavities in the rotors, plus the large, easy entry anti-cavitation ports, the Universal Series of pumps allow efficient pumping of high viscosity fluids, slurries, or even liquids with large chunks or particles.

Finally, because the Waukesha Cherry-Burrell design has no bearings in the fluid being pumped, no sliding or rolling contact and no rotor-to-rotor contact, we get excellent service with every Universal Positive Displacement pump even under sever or abrasive conditions.

Key Applications

Food & Beverage |

Dairy |

Pharmaceutical & Cosmetic |

Chemical & Industrial |

|---|---|---|---|

|

|

|

|

Specifications

|

MODEL |

DISPLACEMENT |

NOMINAL |

INLET/ OUTLET |

OPTIONAL INLET/ OUTLET |

PRESSURE RANGE |

MAXIMUM RPM |

APPROX SHIP WT. |

TEMP RANGE |

|---|---|---|---|---|---|---|---|---|

| 006-U3 | .0082 GAL. (.031 LITER) | 8 GPM (1.8 m3/hr.) | 1.0 in | 1.5 in | 300 PSI (20.7 bar) | 1000 | 56lb (25kg) |

Std Clearance Rotors: |

| 015-U3 | .0142 GAL. (.054 LITER) | 11 GPM (2.5 m3/hr.) | 1.5 in | --- | 250 PSI (17.2 bar) | 800 | 56lb (25kg) |

|

| 018-U3 | .029 GAL. (.110 LITER) | 20 GPM (4.5 m3/hr.) | 1.5 in | 2.0 in | 200 PSI (13.8 bar) | 700 | 65lb (30kg) |

|

| 030-U3 | .060 GAL. (.227 LITER) | 36 GPM (8.2 m3/hr.) | 1.5 in | 2.0 in | 250 PSI (17.2 bar) | 600 | 130lb (59kg) |

|

| 040-U3 | .076 GAL. (.288 LITER) | 46 GPM (10.4m3/hr.) | 2.0 in | --- | 150 PSI (10.5 bar) | 600 | 140lb (64kg) |

|

| 045-U3 | .098 GAL. (.371 LITER) | 58 GPM (13.2 m3/hr.) | 2.0 in | --- | 450 PSI (31.0 bar) | 600 | 295lb (134kg) |

|

| 060-U3 | .153 GAL. (.579 LITER) | 90 GPM (20.4 m3/hr.) | 2.5 in | 3.0 in | 300 PSI (20.7 bar) | 600 | 285lb (129kg) |

|

| 130-U3 | .253 GAL. (.958 LITER) | 150 GPM (34.1 m3/hr.) | 3.0 in | --- | 200 PSI (13.8 bar) | 600 | 305lb (138kg) |

|

| 180-U3 | .380 GAL. (1.438 LITER) | 230 GPM (52.2 m3/hr.) | 3.0 in | --- | 450 PSI (31.0 bar) | 600 | 520lb (236kg) |

|

| 210-U3 | .502 GAL. (1.900 LITER) | 300 GPM (68.1 m3/hr.) | 4.0 in | --- | 500 PSI (34.5 bar) | 600 | 915lb (415kg) |

|

| 220-U3 | .521 GAL. (1.972 LITER) | 310 GPM (70.4 m3/hr.) | 4.0 in | --- | 300 PSI (20.7 bar) | 600 | 590lb (268kg) |

|

| 320-U3 | .752 GAL. (2.847 LITER) | 450 GPM (102 m3/hr.) | 6.0 in | --- | 300 PSI (20.7 bar) | 600 | 895lb (406kg) |

Options

Ports

Standard: Sanitary Clamp Type Is available in a variety of styles including S-Line, I-Line and Q-Line

-

Bevel Seat Available

-

Optional European Types; DIN, SMS, RJT

-

Male NPT and 150 lb. flanges optional on Models 006 through 220 size.

-

150 lb. flanges standard on Model 320.

-

Contact factory for available rectangular flange inlets.

Rotors

Standard: Twin Wing - Standard; suitable for most applications.

-

Single Wing - For reduced breakage on fluids with discrete particulates, such as diced tomato products

Rotor clearance

Standard: up to 300°F (149°C)

-

Low viscosity clearance rotors optional for applications up to 200°F (93°C)

-

Contact application engineering for other rotor clearance options

O-Rings

Standard: Buna-N

Options:

-

PTFE/FFKM

-

Fluoroelastomer (FKM)

-

Fluoroelastomer (FKM) - Class 6

O-Rings

Standard: Fluoroelastomer FKM

Options:

-

PTFE/FFKM

-

Fluoroelastomer (FKM)

-

Fluoroelastomer (FKM) - Class 6

-

EPDM

-

EPDM - SF

-

EPDM - Class 6

-

Silicone

-

Perfluoroelastomer (FFKM)

-

FEP Encapsulates

-

Buna-N - Metal Detectable

-

FKM - Metal Detectable

-

EPDM - Metal Detectable

Seal Options

Standard: Single Mechanical Seal Standard seal configuration: silicon carbide rotary seal face and carbon stationary seal face. Alternate materials available for abrasive service.

Options:

-

Double Concentric Mechanical Seal - Used with flushing fluid to cool, lubricate, flush away residue. Best arrangement for severe service.

-

Single and Double O-ring Seal - Waukesha Cherry-Burrell's traditional general purpose seal. Low cost and easy to service. Suitable for low pressure applications. 100 psi, 7 bar

-

Elastomer choices for o-rings: Fluoroelastomer (FKM), EPDM, Perfluoroelastomer (FFKM)

-

Mechanical seal material options: carbon, silicon carbide, tungsten carbide

Cover & Gearcase

Standard: Stainless steel 17-4 shafts, top shaft position, stainless steel bearing retainers, shaft completely sealed from product zone.

Options:

-

Lower shaft position

-

Bearing isolators

-

Pedestal shims for side mounted pumps. Left hand shaft position is standard

-

Right hand shaft is positioned on side mounted gearcase

Shaft Position

Standard: Top shaft position

Options:

-

Lower shaft position

Mounting

Standard: Flat plate, epoxy painted, with adjustable feet, SS coupling guard, and Lovejoy or Woods coupling standard.

Options:

-

304 SS unpolished plate base with adjustable feet

-

Portable base with rubber wheels

-

SS tubular bases

Bases & Drives

Standard: Stainless steel tubular base with adjustable feet and stainless steel guard and coupling standard

Options:

-

304 SS plate.

-

Flat epoxy plate.

-

Portable base.

-

Tru-Fit®

Close coupled Tru-Fit® pump mounted on stainless steel base with stainless steel adaptors standard.

Features:

-

No shaft alignment necessary. No coupling guard required.

-

Special base design enhances cleanability.

-

Reduces overall length of complete unit by an average of 20-25%.

-

Average of 20-25 gear ratios available per horsepower.

-

Separate oil sump for gear reducer and timing gears.

-

Options:

-

304 SS polished plate base.

-

NEMA or IEC frames available. Right angle reducer also available for

additional space savings. -

1/2 through 60 horsepower drive options available.

-

Horizontal or vertical porting.